FAST ceramics to develop low energy, low temp ceramics manufacturing process

FAST Ceramics and the University of Colorado have completed an exclusive option agreement to allow the company to develop a faster, energy-efficient technique for manufacturing the ceramic materials used in aerospace, medical implants, military defense armor and a wide variety of technical applications, in addition to traditional ceramics like tableware and architectural tiles.

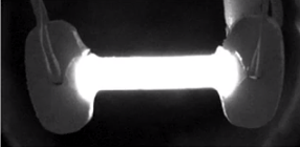

Ceramic materials are produced by sintering: solidifying ceramic powders at high temperatures in a process that is extremely energy intensive. However, the technique developed by a research group at CU’s Boulder campus works by applying an electrical field during the sintering process, which then requires significantly less energy and lower temperatures. The process is called Field-Assisted Sintering Technology, or FAST. For example, stabilized zirconia (used to produce fuel cells, among other applications) is sintered at 1400 degrees Celsius for many hours in a traditional process; using FAST, the same zirconia can be sintered in a matter of seconds, at a furnace temperature of 800 degrees Celsius.

The technology portfolio covered by the option was developed by Rishi Raj, a professor in CU-Boulder’s mechanical engineering department, and John Francis and Marco Cologna, at that time both researchers in the same department.

“We are developing technology that could potentially revolutionize the way that ceramics are manufactured in the future,” said Francis, president of FAST Ceramics. The company is currently working on a Small Business Innovation Research (SBIR) grant from the National Science Foundation to help develop a new single-step flash-sintering process for use in solid oxide fuel cells.

“The FAST sintering technique represents an impressive leap forward in ceramic manufacturing,” said Molly Markley of the CU Technology Transfer Office. “The process could have wide applicability across the industry, and we’re eager to see FAST Ceramics further develop and implement the technology.”

FAST (Field Assisted Sintering Technology) Ceramics is a research company dedicated to investigating the effects of electric and magnetic fields on sintering behavior such as flash sintering and flash-sinterforging. They specialize in the design and build of flash-sintering instruments, the design of experiments, microstructural characterization of materials, mechanical characterization of materials, and material testing of high-temperature ceramics and alloys. http://fastceramics.com.